BYSNOWYDHBOATWORKS JULY 19, 2019

Recovery from surgery was long and difficult (and still is), but as soon as I was physically able I got straight back to work.

Fairing frame faces and the inner stem – December 2018

One of the big challenges I’ve faced has been preservation of hull shape. Through repair work over the years, asymmetric loading, and various other things there were several areas of unfairness and asymmetry in the hull. Since her original lines weren’t recorded, and everything was so degraded and delicate, I elected to frame piece by piece to the original hull and try to sort it all out later – rather than try to resolve shape issues in the framing process. I think on the whole this approach was the best one, as anything more aggressive would have risked compromising the structure and losing everything (I put my foot through several planks, and many of the frames fell apart at a touch) – but was also quite a lot more work, I think.

Relatively intact examples of frames and planks. In the worst cases, some planks were about 1/3 dutchmen – December 2018

The two big areas that I wish I had handled more efficiently were the midship area (buckled outward a bit from removing the centreline hog) and the port forward topsides – for some reason in Greece back in 1975 the sheer strake and first strake down were redone as a single super wide board, and the stiffness of it combined with the already aging frames significantly flattened the hull. Rosalind was about an inch and a half narrower on port up forward, it turned out – I’ve managed to reduce that to about 3/4″, which is about as aggressive as I’m comfortable with.

Knightheads under construction – January 2019

Now, don’t get me wrong – I’m making some changes to her original construction and layout, for instance the addition of knightheads to reinforce the bow, layout of the hold to maximise living area and ultimately cargo capacity, strengthening the centreline assembly, and so forth. But as I go along and replace almost every single piece of this old boat, the philosophical debate of the ship of Theseus inevitably comes to mind – at what point is it no longer the same thing?

Installing the new foremast step. Luggers seldom had keelsons, and the foremast step often only spanned 2 floors. In this version it scarphs into the keelson, bolts through 5 floors, and laps onto/bolts through the forefoot knee – February 2019

I’ve had an awful lot of time to ponder this… and what I’ve arrived at is that her shape is her essential character – so I have generally taken a conservative approach to correcting shape issues. In short – things like hog, centreline twist, and midship buckling are issues which could adversely effect performance and longevity but if she’s a bit wider on one side than the other… she’s an old girl. She’s not only entitled to a few idiosyncrasies, but those idiosyncrasies feel like a part of her identity.

Felling frame stock in upstate NY. Note the flying tree… my directional felling skills aren’t always up to trees this tall, growing this close together – December 2018

In the end I think I felled about 2/3rds of Rosalind’s new framing myself – largely on my family’s property in Fishers NY, which is 11 acres of mixed woodland (and most importantly, a lot of black locust). I also milled about 1/2 of that myself, using a my chainsaw and an alaskan chainsaw mill (which is a lot of work, but a really wonderful invention). In all I replaced 159 of 160 floors and futtocks – 2 more original pieces I hope to reuse elsewhere.

Locust tends to ripple like this when it grows in a tight curve – almost too pretty to use! – February 2019

Milling the last few futtocks with my new curvy alaskan mill rail – March 2019

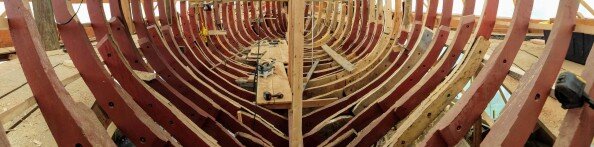

Framing complete. Inside faces still need to be faired – May 2019

Disposing of the old Perkins – February 2019

I also decided that it was time to say goodbye to the old 95HP Perkins, which having been underwater twice was completely seized, and with a dry weight of around 1300 pounds was just a bit much, to my way of thinking anyway. And, y’know. Scrap money helps.

Angelique outer sternpost installed – February 2019

Great but peculiar old Boshco left-handed bandsaw on loan from the estimable Mr. Wheble – March 2019

I also found a source of hackmatack, or Eastern larch by way of craigslist of all things. The price was good, and was one of my top choices to substitute for the original pitch-pine. The pile is stacked, covered, doused in borate, and waiting til the autumn when it will hopefully be dry enough to start using.

4 loads of eastern larch for planking – April 2019

A new Danish white oak beam shelf (/sheer clamp, depending on where you learned the names for things) is now in as well. This meant a lot of fussing over the sheer line (the curve of the topmost plank, which is the most visually distinctive line of any given hull), which is difficult with a boat in a shed surrounded by trees, a house, and several other boats! But after much clambering and squinting and late night laser hijinks and setting up a stepladder in the back of my truck etc. etc. I think it came out pretty well.

Doing my best to sight the sheer line from the deck of Klang II – May 2019

Beam shelf section steaming in situ – May 2019

Also just briefly, I have launched a Patreon site at

https://www.patreon.com/restoringrosalind

If any of you are willing and able to support me in this mad mission of mine, Rosalind and I would of course be enormously grateful.

That’s it for today, thank you for reading! More on steam bags, steam generators, how to do awkward heavy things by yourself with a dodgy shoulder and a bad back, and many other things to come.